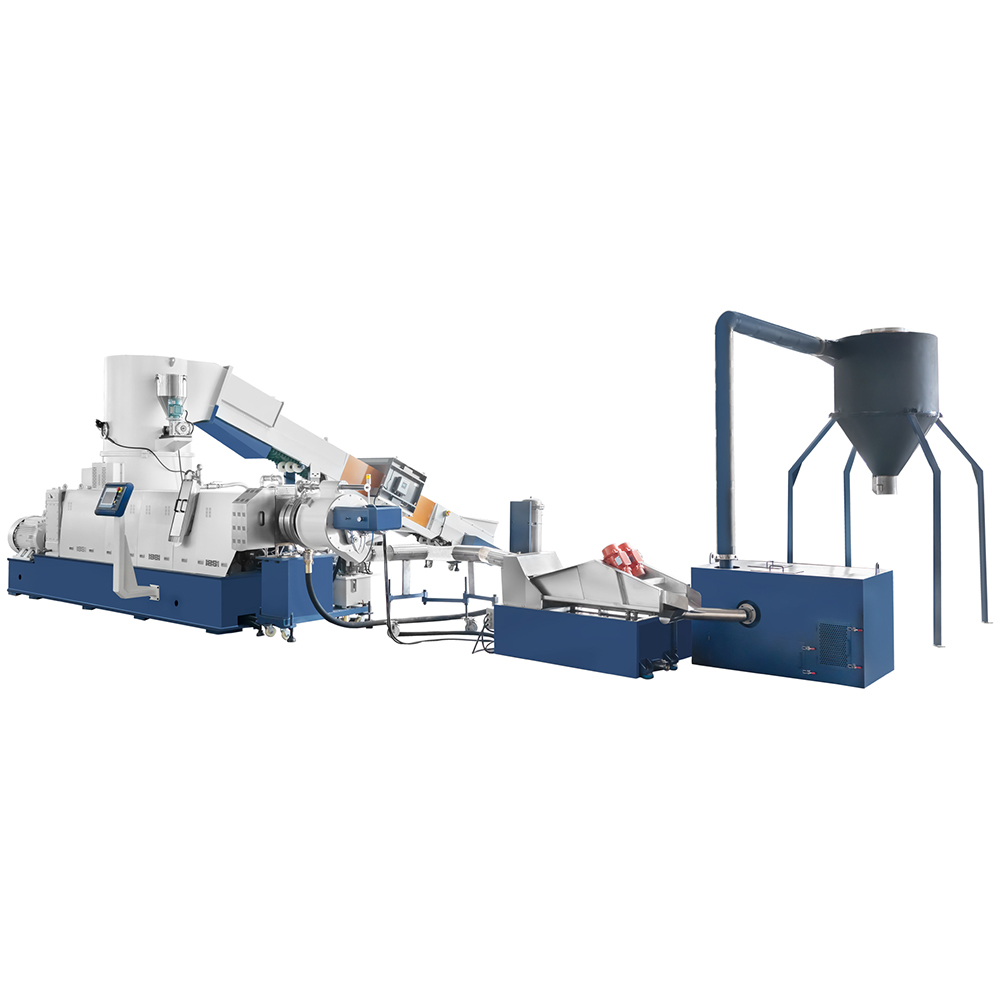

PP PE Firimu Recycling Extruder Machine ine Shredding Agglomerator

Vhidhiyo Yechigadzirwa:

PP PE firimu recycling extruder muchina ane shredding agglomerator/cutter compactor

Kugadzirisa Material Mifananidzo:

Processing Material:

HDPE, LDPE, LLDPE, PP, akadai semafirimu, mabhegi, maflakes, mafirimu rollers, firimu rakatambanudzwa, firimu rekudzikirira, firimu re-multi-layer, T-shirt bag rakachekwa.

Foamed PE, EPS uye XPS: rolls, bhegi, pepa, chigadziko chekudya, mambure emichero, chivharo

Textile: PP fiber, raffia, silika, shinda, bhegi rakarukwa, jumbo bag

Features:

Iyi compactor yakasanganiswa pelletizing sisitimu inobatsira yakadzokororwa zvinhu pasina pre-kucheka

Compacting kuwana akashongedzerwa nekucheka mavharuvhu, ayo aishandiswa kudzora zvinhu kudyisa kumhanya

Vacuum system yekupedza mvura kana gasi zvakanyanya

Yakanakisa hydraulic skrini sefa ine yakatsiga kudzvanywa kwekusamira, hapana-kudonha

Kuchengetedza magetsi nekubuda kwepamusoro (0.28kwh/kg)

General working process:

1.Belt conveyor kutamisa zvinhu kupinda shredding compactor.

2.The interlock control system pakati pebhandi rinoendesa kune uye shredding compactor inovimbisa kuenzanisa kudya pasina yakanyungudutswa compactor.

3.Pazasi pe shredding compactor, pane imwe cutter board.ne centrifugal force, zvinhu zvakadzokororwa zvinotanga kuchekwa nemukati ma rotary cutters uye stationary cutters.

4.After izvozvo, zvinhu zvinopinda degassing screw kubva kurutivi compactor.

5.Nekupisa kupisa, plastiki inova semi-plastification zvinhu.

6.Uyezve, semi-plastiki zvinhu zvinochekwa kuita pellets.

Main Technical Parameter:

| Model | ML75 | ML85 | ML100 | ML130 | ML160 | ML180 |

| Siruvha dhayamita (mm) | 75 | 85 | 100 | 130 | 160 | 180 |

| L/D | 26 kusvika ku37 | |||||

| Kubuda (kg/h) | 100-180 | 180-250 | 250-350 | 500 | 600-800 | 1000 |

Machine Mifananidzo:

Single screw extruder

Double stage recycling extruder

General Information:

| Zita remuenzaniso | ML |

| kubuda | Plastic pellets/granules/resin/plastic raw material |

| Zvikamu zvemuchina | Belt conveyor, cutter compactor, main extruder, pelletizing unit, kutonhora system, silo, cabinet |

| Kudzokorora zvinhu | PP/PE/LDPE/HDPE firimu, bhegi, faibha |

| Capacity range | 100kg/h kusvika 1200kg/h |

| Kudyisa nzira | Conveyor, roll yekutyaira system |

| Screw dhayamita | 75mm kusvika 200mm |

| Screw L/D | 26 kusvika ku33 |

| Kurukura mbishi zvinhu | 38CrMoAl kana bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Kucheka mhando | Vertical pelletizing nzira, dhonza strip pelletizing |

| Kutonhora mhando | Mvura inotonhorera, mhepo inotonhorera |

| voltage | Customized |

| Optional devices | Metal detector, mvura inotonhora system, feeding silo, vibration system |

| Delivery nguva | 40 kusvika 60 mazuva |

| Warranty nguva | 13 mwedzi |

| Zvitsigiro zvehunyanzvi | Chimiro chemuchina, dhizaini yekuisa, injinjiniya mhiri kwesevhisi |

| Chitupa | CE/ SGS/TUV/CO |

Sei tichisarudza isu?

A.PURUI ine nyanzvi yekugadzira kubva 2006. tine yedu tekinoroji dhipatimendi rekugadzira.Imwe neimwe extruder inogadzirwa zvinoenderana nechinhu chimiro.

B.Kuchengetedza Simba nekubuda kwepamusoro

C.Quality guaranty nguva i12 mwedzi kubva pazuva reBill of Lading.

D. Delivery nguva: 40 kushanda mazuva kusvika 60 mazuva

E.Ship yakakumbirwa pasuru

F.Machine installation iripo.Zvinotora anenge 5 kusvika 7 mazuva nekupedzisa imwe nguva yekuisa.Iye akapihwa mainjiniya (s) anotungamira kudzidziswa kwemushandisi wemuchina, kushanda kwemuchina uye komisheni.

Nhanganyaya yekambani:

Chengdu PuRui Polymer Engineering Co. Ltd ndeimwe yevanogadzira zvigadzirwa zvemapurasitiki ekudzokorodza michina, extruder, epurasitiki granulator uye zvine chekuita nemidziyo yekubatsira muChina.Yedu yepurasitiki pelletizing system yakasarudzika mabhenefiti ari screw dhizaini, yakakwira kuburitsa, yakanaka degassing uye yakanaka sefa maitiro.Yedu yepurasitiki yekuwachisa tambo senge crusher ine inotakurika kuramba uye inopinza cutter, washing units, kupatsanura kana kuronga muchina, drying system, uye yekurongedza system ndeyemhando yemhando.

Muchina wepurasitiki wekudzokorodza uye wekugezera imhando yemidziyo inoshandiswa kudzoreredza marara epurasitiki kuita magranules kana pellets anogona kushandiswa zvakare mukugadzira zvigadzirwa zvepurasitiki zvitsva.Muchina uyu unowanzo shanda nekutsemura kana kukuya tsvina yepurasitiki kuita zvidimbu zvidiki, wobva wanyungudusa nekuiburitsa kuburikidza nefa kuti igadzire mapellets kana magranules.

Kune mhando dzakasiyana dzemapurasitiki ekudzokorodza uye michina yegranulating iripo, kusanganisira imwe-screw uye mapatya-screw extruder.Mimwe michina inosanganisirawo mamwe maficha akadai semasikirini ekubvisa tsvina kubva mumarara epurasitiki kana kutonhora masisitimu kuti ave nechokwadi chekuti mapellets akasimba.PET bhodhoro rekusuka muchina, PP yakarukwa mabhegi ekuwachisa mutsara

Plastic recycling uye granulating machines inowanzoshandiswa mumaindasitiri anogadzira marara epurasitiki akawanda, senge kurongedza, mota, uye kuvaka.Nekudzokorodza marara epurasitiki, michina iyi inobatsira kuderedza kukanganiswa kwezvakatipoteredza kwekuraswa kwepurasitiki uye kuchengetedza zviwanikwa nekushandisa zvakare zvinhu zvaizoraswa.

Lithium bhatiri rekudzoreredza bhatiri imhando yemidziyo inoshandiswa kudzoreredza uye kudzoreredza zvakakosha kubva kumabhatiri e-lithium-ion, ayo anowanzo shandiswa mumidziyo yemagetsi senge masmartphone, malaptop, uye mota dzemagetsi.Midziyo yacho inowanzoshanda nekupwanya mabhatiri muzvikamu zvawo, senge cathode uye anode zvinhu, electrolyte mhinduro, uye simbi foils, uyezve kupatsanura nekuchenesa zvinhu izvi kuti zvishandiswezve.

Kune mhando dzakasiyana dze lithium bhatiri recycling michina iripo, kusanganisira pyrometallurgical process, hydrometallurgical process, uye mechanic process.Pyrometallurgical maitiro anosanganisira kupisa-kupisa kwemabhatiri kudzoreredza simbi semhangura, nickel, uye cobalt.Hydrometallurgical process inoshandisa kemikari mhinduro kunyungudutsa zvikamu zvebhatiri uye kudzoreredza simbi, nepo mechaniki maitiro anosanganisira kupwanya uye kugaya mabhatiri kuti aparadzanise zvinhu.

Lithium bhatiri recycling mudziyo wakakosha kudzikisa kukanganiswa kwezvakatipoteredza kwekuraswa kwebhatiri uye kuchengetedza zviwanikwa nekudzoreredza simbi dzakakosha uye zvinhu zvinogona kushandiswa zvakare mumabhatiri matsva kana zvimwe zvigadzirwa.

Pamusoro pezvakatipoteredza uye zviwanikwa zvekuchengetedza mabhenefiti, lithium bhatiri recycling michina zvakare ine mabhenefiti ehupfumi.Kutora simbi dzakakosha uye zvinhu kubva kumabhatiri akashandiswa kunogona kuderedza mutengo wekugadzira mabhatiri matsva, pamwe nekugadzira mitsva yemari yemakambani anobatanidzwa mukugadzirisa zvakare.

Uyezve, kuwedzera kuri kuita kudiwa kwemotokari dzemagetsi uye zvimwe zvigadzirwa zvemagetsi kuri kufambisa kudiwa kweindasitiri inoshanda uye yakagadzikana yekudzokorodza bhatiri.Lithium bhatiri recycling michina inogona kubatsira kuzadzisa ichi chinodikanwa nekupa yakavimbika uye inodhura nzira yekudzoreredza zvinhu zvakakosha kubva kumabhatiri akashandiswa.

Nekudaro, zvakakosha kuti uzive kuti lithium bhatiri recycling ichiri indasitiri nyowani, uye pane zvimhingamipinyi zvekukunda maererano nekugadzira inoshanda uye inodhura kudzokorora maitiro.Pamusoro pezvo, kubata kwakanaka uye kuraswa kwemarara ebhatiri kwakakosha kudzivirira nharaunda uye hutano njodzi.Naizvozvo, mirau yakakodzera uye nhanho dzekuchengetedza dzinofanirwa kunge dziripo kuti ive nechokwadi chekubata zvine hungwaru uye kudzokororwa kwemabhatiri e lithium.